Concrete Pipe Seals

Concrete pipe seals are used to create watertight and secure connections in concrete pipe systems. These seals are essential in applications where the transportation of fluids, such as wastewater or stormwater, requires a reliable and leak-free connection. Concrete pipe seals help to prevent water infiltration, soil erosion, and contamination. Here are some key points about concrete pipe seals:

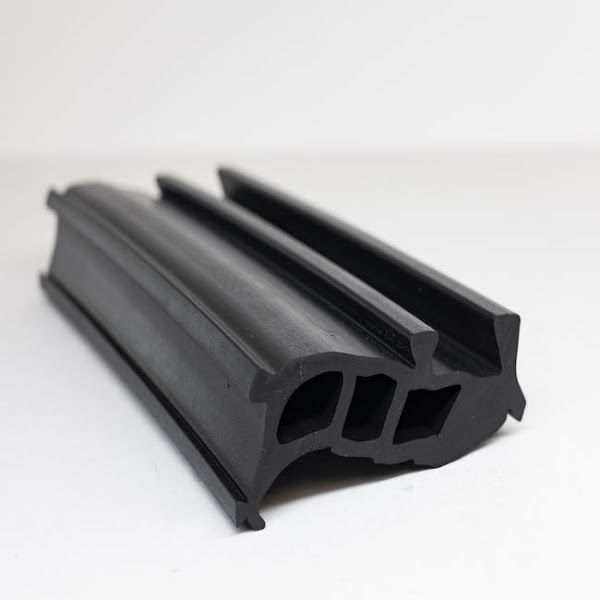

1. **Material**: Concrete pipe seals are typically made from elastomeric materials, such as rubber, EPDM (Ethylene Propylene Diene Monomer), or other synthetic rubber compounds. These materials provide the flexibility and sealing properties required for creating a reliable seal in concrete pipe systems.

2. **Sealing Function**: The primary function of concrete pipe seals is to create a watertight and airtight seal between concrete pipes or between concrete pipes and other pipe materials. They prevent leakage of fluids, gases, and the ingress of external elements like water, soil, or contaminants.

3. **Applications**:

- **Wastewater Systems**: Concrete pipe seals are commonly used in wastewater and sewer systems to create tight connections and prevent sewage leaks into the surrounding soil and groundwater.

- **Stormwater Drainage**: They are employed in stormwater drainage systems to channel rainwater and prevent soil erosion and flooding.

- **Culverts and Water Conduits**: Concrete pipe seals are used in the construction of culverts and water conduits to ensure that water flows through these structures without leakage.

- **Infrastructure and Construction**: In construction projects, they are used in pipelines for various purposes, including water supply, drainage, and irrigation.

4. **Design and Configuration**: Concrete pipe seals come in various shapes and sizes, such as O-rings, gaskets, and profile seals. The design is tailored to the specific requirements of the application and the type of concrete pipe connection.

5. **Installation**: Proper installation of concrete pipe seals is essential to ensure their effectiveness. Installation often involves placing the seal between pipe sections, using sealants or gaskets to secure the connection, and ensuring that the connection is tightly sealed to prevent leaks.

6. **Maintenance**: Regular inspection and maintenance of concrete pipe seals are necessary to identify any wear, damage, or signs of degradation. Damaged seals should be replaced promptly to maintain the integrity of the pipe system.

Concrete pipe seals are critical components in infrastructure and construction projects where durable and watertight connections are required. They help prevent water contamination, soil erosion, and other environmental issues associated with leaks in wastewater and stormwater systems. Proper selection, installation, and maintenance of these seals are key factors in ensuring the reliability of concrete pipe connections.

Yorumlar

Yorum Gönder